Automated Surface Scanning System to

Detect Textile Shade Differences

Challenge

A major textile manufacturer was seeking a technology to differentiate very small shade differences in its manufacturing plant. Quality control human observers at the plant and at the various customers after the delivery of the products disagreed on the scale of these differences, thus an objective instrumentation was required to resolve those disputes.

Solution

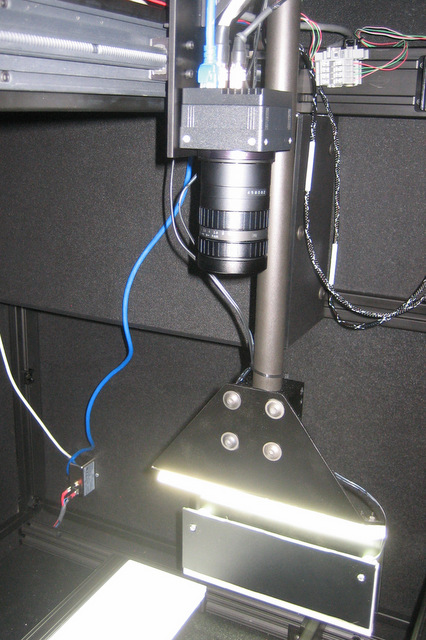

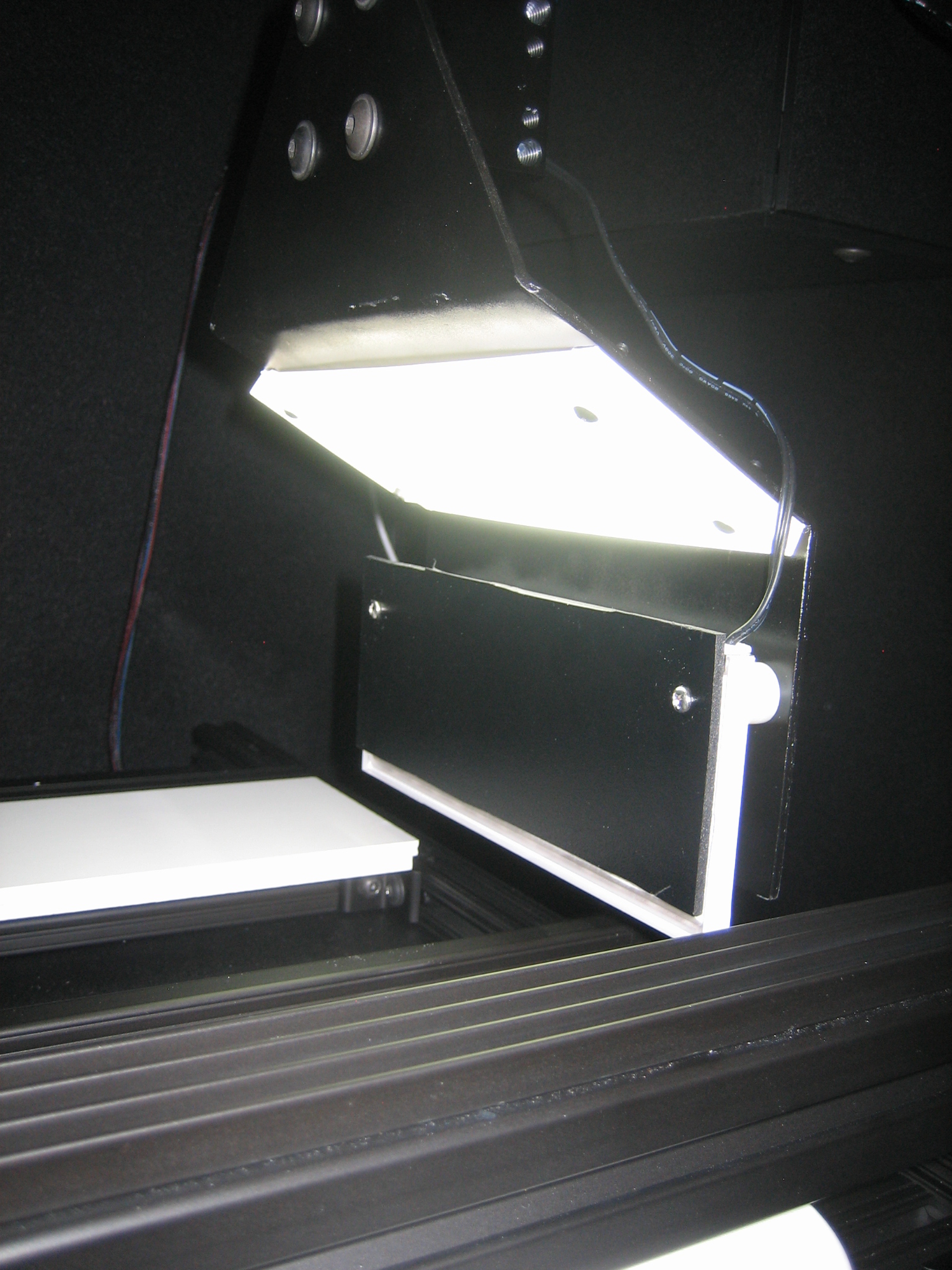

MSV developed a complete automated system to scan the surface of the samples, calculate the differences and compare them to an industry standard test chart. Internal referencing and inclusion of the standard in every measurement was necessary to achieve differentiation. This challenging application required a flexible system that: included a standardized presentation of samples more than 6-feet long, indicated the areas to be evaluated for scanning, and included a very reproducible multi-angle dual light source and reproducible camera movement to avoid any saturated pixels from specular reflections. Additionally, a complete dedicated software suite was necessary to present the results.