Pharmaceutical Manufacturing

Challenge

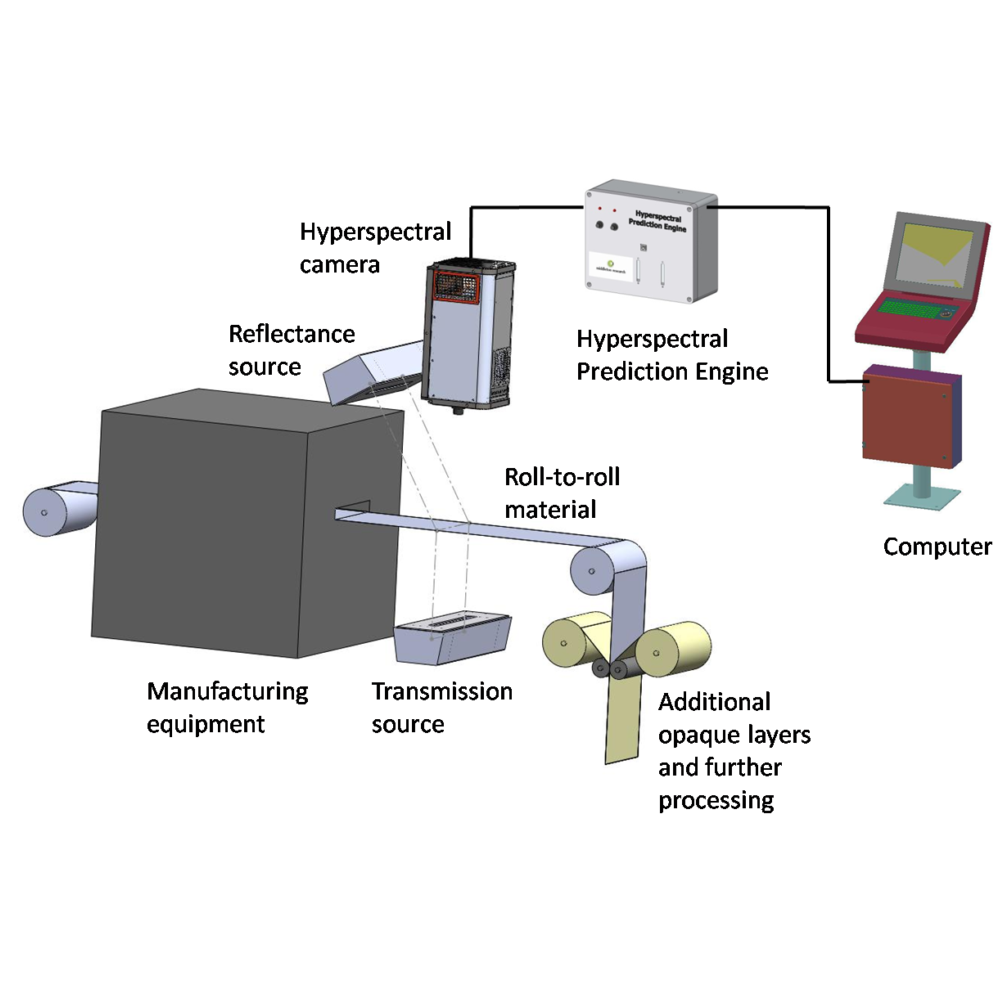

A Fortune 500 pharmaceutical company producing transdermal patches was interested in monitoring the composition of the entire wide production web in its roll-roll manufacturing lines.

Solution

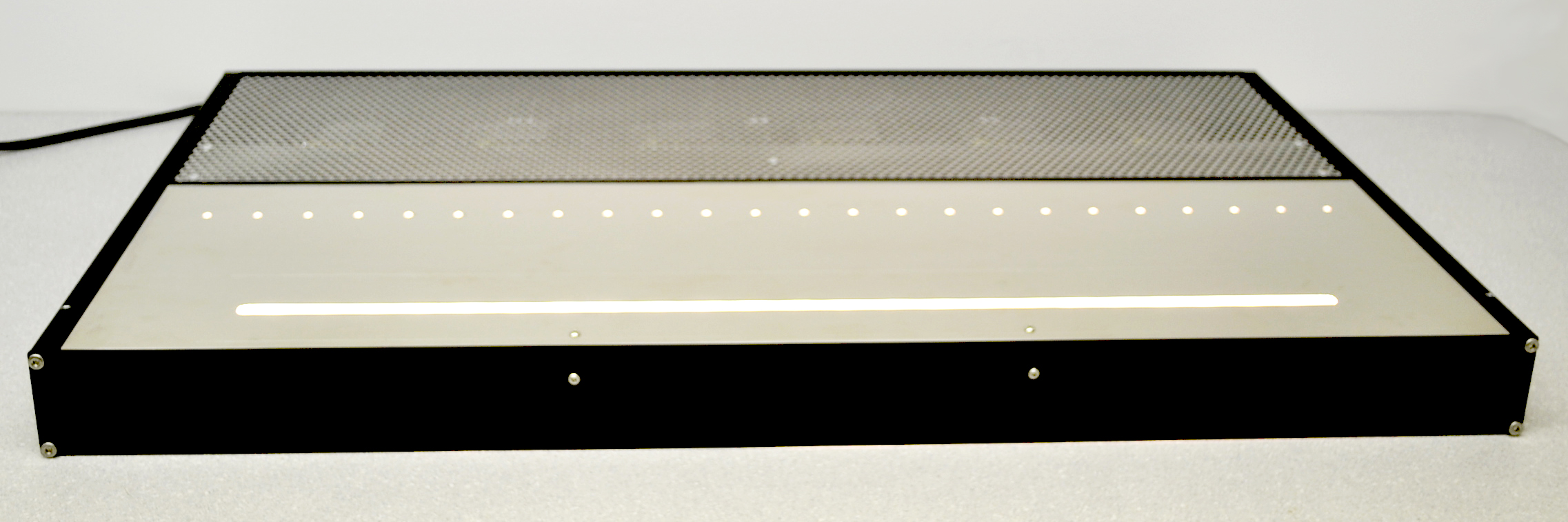

For the process monitoring a Stirling-cooled SWIR hyperspectral camera (1000-2500 nm) coupled with a 36” wide diffuse transmission light source was developed. A line-light with 24 halogen lamps in a row provided a diffuse light for the transmission measurement through the production film. The special software was able to predict the unit dose of all products die-cut downstream from the web. The CFR compliant software developed controls the camera, collects dark readings periodically, and is also able to calculate thickness and composition in real-time and to communicate with the production floor OPC server, saving the appropriate witness data and informing the operator if the set parameters reach warning or alarm levels.