Testing the Integrity of Plastic Medical Seals with

Fiber Optics-Based Hyperspectral Imaging

Challenge

A major medical supply manufacturer was seeking a simple and non-destructive method for in-production testing of a plastic seal in a round part. The previous method involved sampling from production and destructive wet pressure testing.

Solution

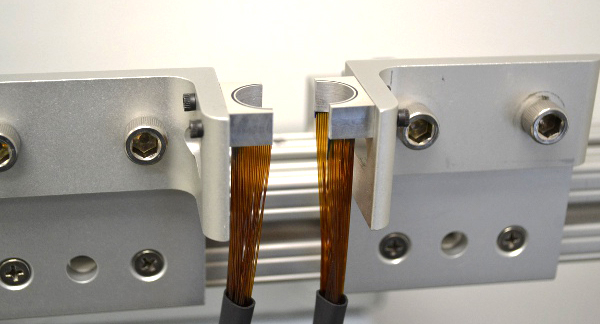

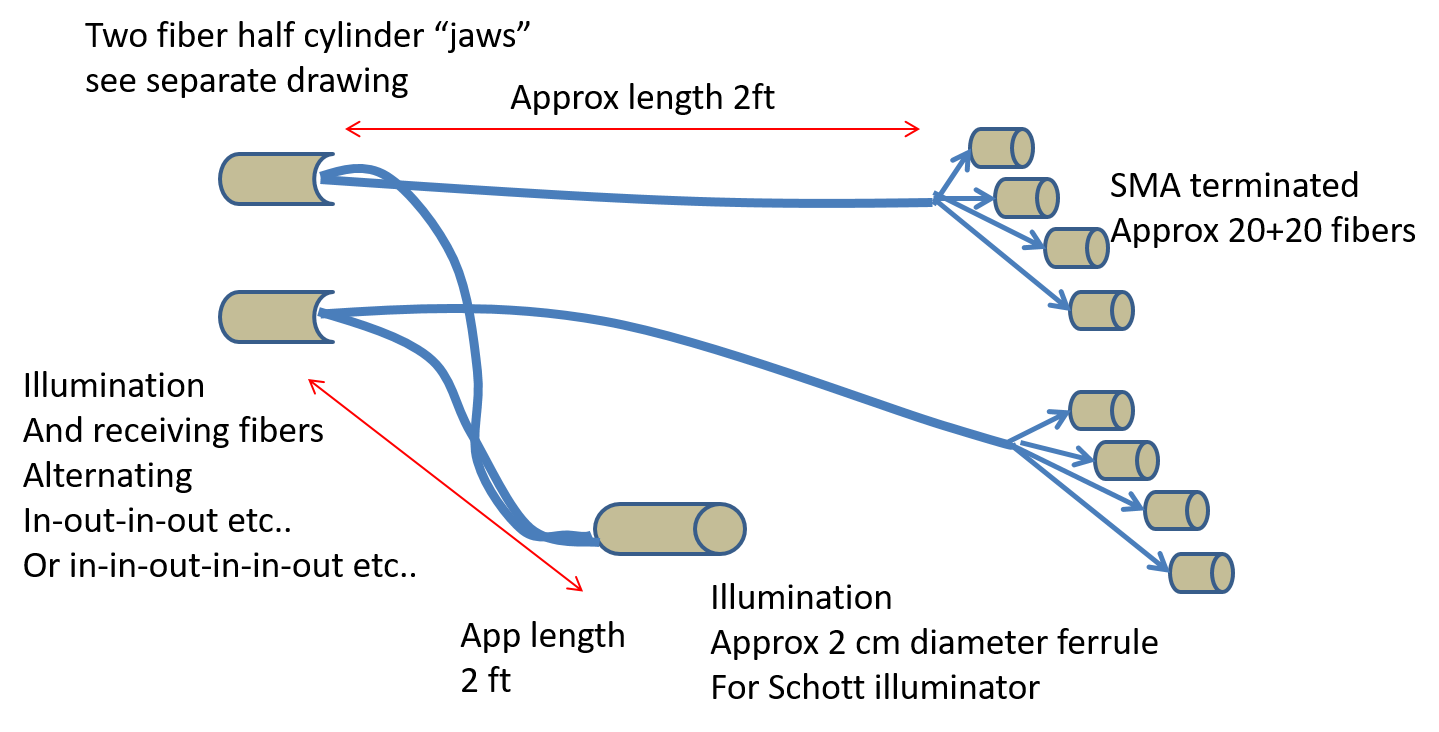

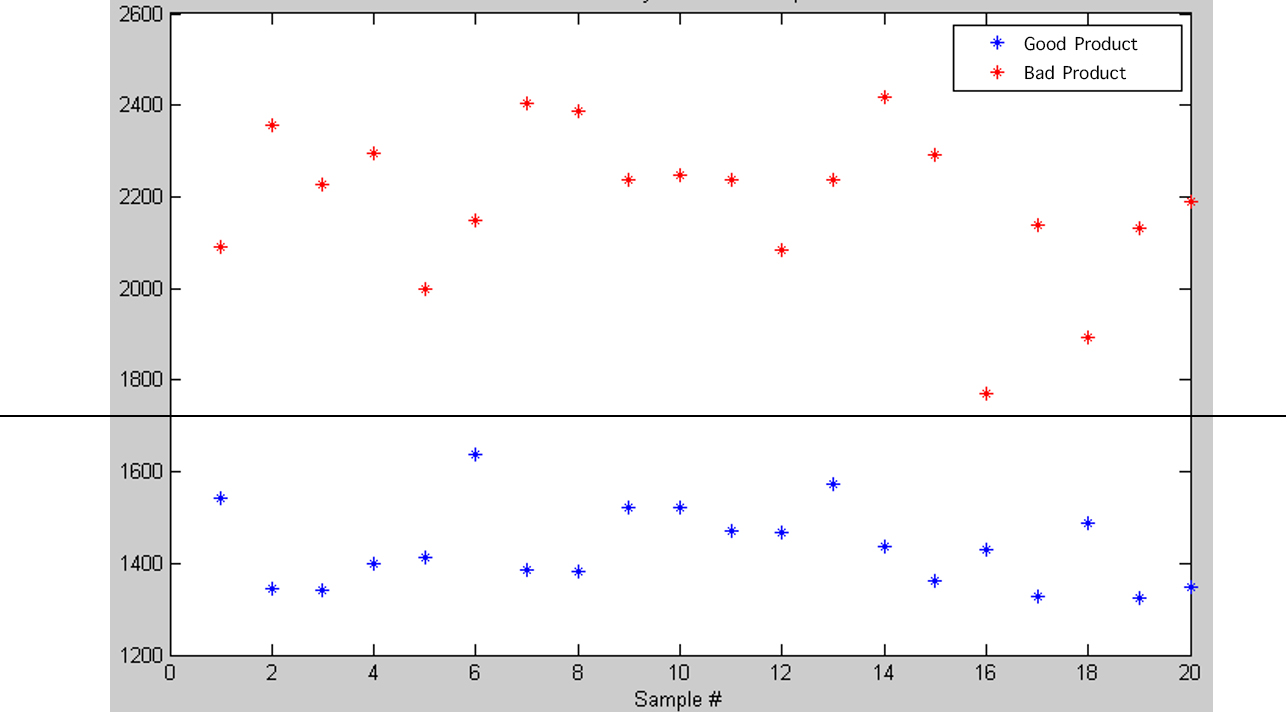

MSV developed a fiber optics-based multi-point hyperspectral method for testing this seal. The identification and position of defects can now be clearly identified from spectral changes. A fiber ring was manufactured to fit the parts to be tested and the other end of the bundle was connected to a near-infrared hyperspectral camera. The system is able to alert the manufacturer to the presence of defects as well as their locations and sizes. The use of this 100% non-destructive and cost-effective rapid testing in the manufacturing of medical devices saves money and increases the reliability of parts, thus reducing the chance of leakage or contamination, which are hazardous to patients.