Hyperspectral Robot for Detection of Defects in

Composite Airframe Manufacturing

Challenge

A major commercial airplane manufacturer approached Middleton Spectral Vision to help with the full characterization of a particular type of defect.

Solution

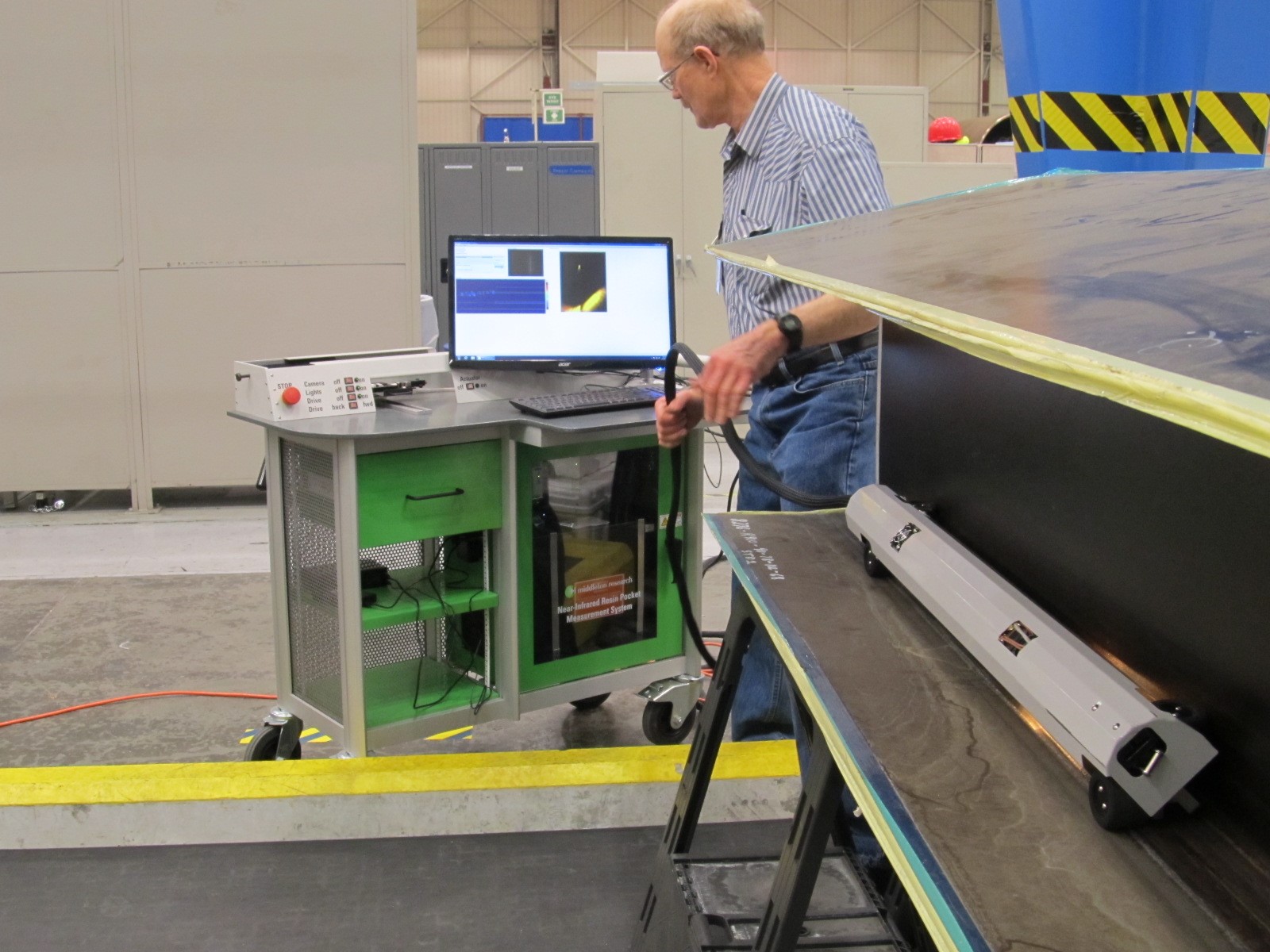

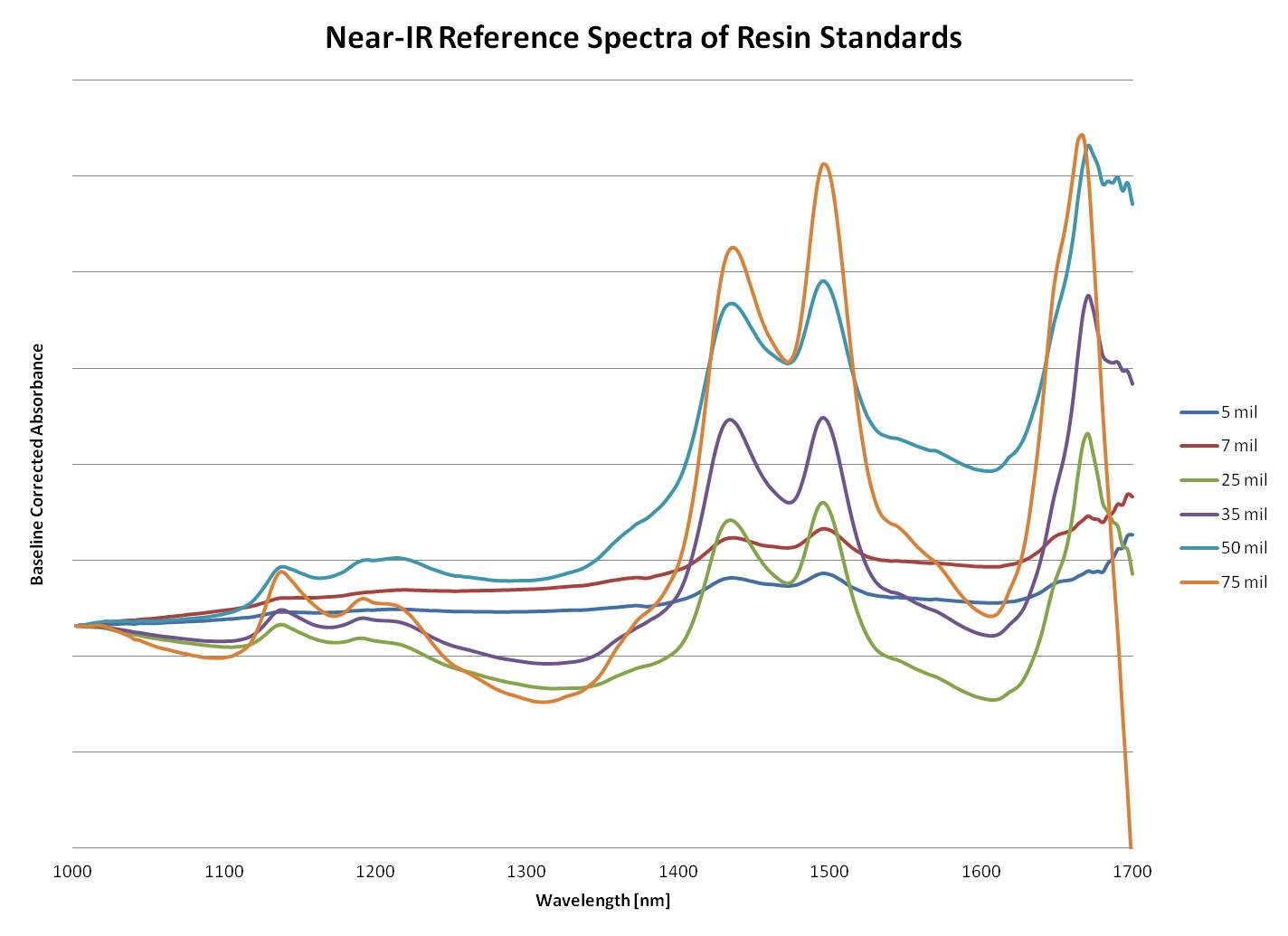

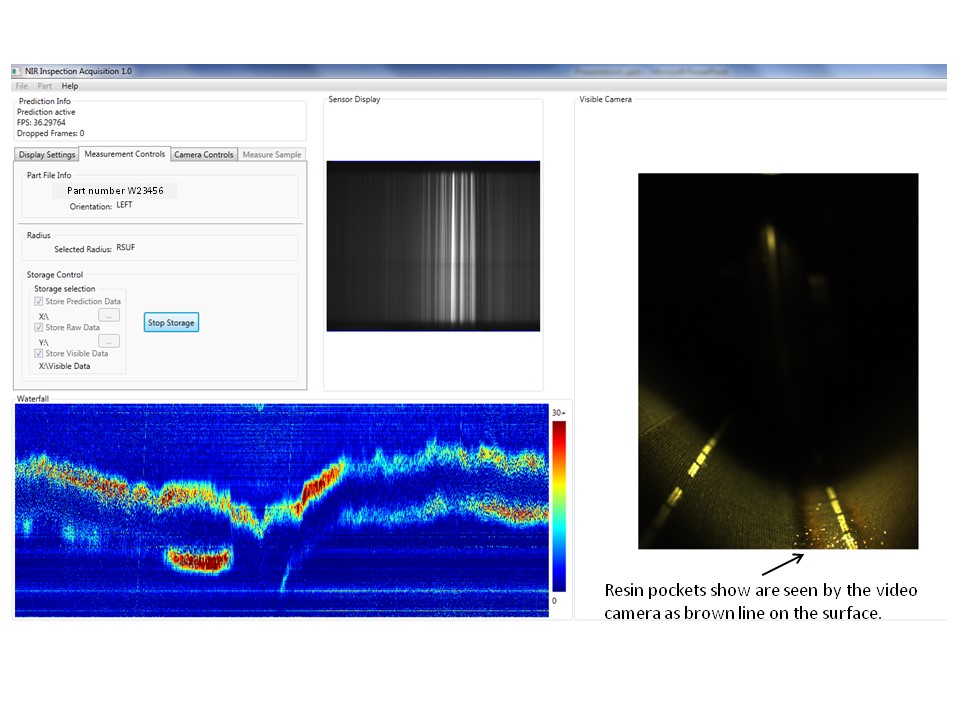

Middleton Spectral Vision developed a hyperspectral robot that is able to scan the surface of the composite airframe and report the exact location, width, length and depth of the defect. The complete instrument with hardware, a dedicated control and calibration software is deployed worldwide at several production sites. With a built-in calibration station, the device is producing NIST-traceable dimensional and depth information in a detailed report including the airframe part, the location, full characteristics of the area along with images and witness pictures for further review by the quality personnel of the manufacturing organization.

The work resulted in several patents and a prestigious Invention Award from the company, the only award granted to outside parties in 2015.

Related Publications:

A Hybrid Numerical and Imaging Approach for Characterizing Defects in Composite Structures